Lakeside Tools

Model 84-20

I suppose there's no need to add the word "vintage" to the title, not when it comes to "Lakeside" tools. That's because Montgomery Ward is another of those department store giants we lost to online commerce. Sad, if you ask me. And, as you'll see shortly, I've restored a couple Montgomery Ward tools, one of which was a Lakeside. While not earthshattering, it is interesting that Wards had a couple tool brands, and maybe it'll be fun to explore that for a minute.

The Ol' Monkey Wards!

Wards Master Quality was a brand used by Montgomery Ward & Co., a mail order company out of Chicago, and a direct competitor to Sears. Although Wards were in business from 1872 through 1997 the Wards Master Quality brand was probably only used between the 1920s and the early 1940 when it was discontinued because of the cut-backs that arose from WWII. At some point, Wards tool line became Lakeside, as I talked about with my tin snips post.

Mind you, like Sears and Craftsman, Montgomery Ward didn't actually make tools themselves but contracted for all kinds of goods, including tools, manufactured for them with their own brand on them. Finally, Montgomery Ward tools had three levels of quality:

- Eclipse Quality-Good

- Lakeside Quality-Better

- Master Quality-Best

Montgomery Ward & Lakeside Tools

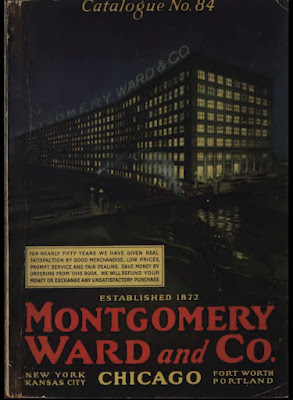

If you're old enough to remember the halcyon days of the great department stores and their catalogs, you probably remember Montgomery Ward. Much like Sears with the Craftsman line, Montgomery Ward had a line of tools called Lakeside Tools. Lakeside Saw & Tool Co. was started in January, 1908, was a subsidiary of Montgomery Ward & Co. Other subsidiaries in 1911 were Lakeside Foundry Co. and Lakeside Implement & Vehicle Co. It seems both Sears and Montgomery Ward were into everything! This is the old Montgomery Ward building in Albany, NY:

Inherited

So this is another one of the tools I inherited from the grandfather of my former boss. It's kinda cool, of all the tools that came in the two toolboxes, this and another saw were well-packed in a kind of brace system built into the lid of one of the handmade boxes.

So, What Are We Looking At?

Although the tools in my inherited tool box have been sitting around for nearly a century, this saw was in remarkable good condition. As you can see below, the blade itself, while dirty and a little rusty, wasn't nearly as bad as some of the other tools in the box. And it certainly wasn't as bad as the saw I salvaged from my neighbor back in August of '21. Here's the Lakeside...

Many of us who grew up in the 1900s—the golden century of consumerism—were raised on brand loyalty just as surely as we were raised on Howdy Doody, AM radio, and My Weekly Reader. For example, in my household our cars were Chevys, our milk was Boswell’s, our bread was Baird’s, our supermarket was Buddie’s, our soda pop was Dr Pepper, our soft ice cream was Dairy Queen, our aftershave was—can we be forgiven?—Old Spice.

And our department store was Montgomery Ward.

The only charge card that some of us ever saw in our father’s wallet was one for Montgomery Ward. Our childhood memories of poring over the Ward’s Christmas catalog to compile our wish list and then, in the Ward’s catalog order department, having to “take a number” to begin the (seemingly) interminable wait with our parents..." - Hometown by Handlebar, August 12, 2022

The first, and simplest step in restoring the saw was to soak the blade in Evaporust. I let it soak overnight and that was all it took! Like I said - not in bad shape at all.

Then it was just a matter sanding. I used my orbiting sander, then sanded by hand. I really wanted to be care to preserve the etching on the blade.

And here's a look at the etching on the saw. This first one shows the "Montgomery Ward piece:

And this second one shows it's a Lakeside Model 84-20:

Faint as it is, I was able to preserve it sufficiently that the etching is still visible in person.

The Handle

Just as with the blade, the handle was in decent shape. The single most important problem with the handle though was that there was a crack at the bottom that definitely needed to be addressed.

After considering my options, I decided to put a peg in through the bottom of the handle. I started with a Forstner bit in my drill press...

And then, with some Titebond glue, I drove the peg in so that it was half in the portion of the handle above, and half below the crack.

After clamping overnight, I sawed off the remainder of the peg.

There was also a couple chips out of the handle horns, so I fixed them too.

Then, I sanded it all down...

And after a couple coats of Minwax Polyshades Bombay Mahogany stain, she was looking nearly brand new! - Nearly...

And yes, I lost one of the screws, I have new ones coming.

And Now I Have A New Saw!

And just like that I have another saw. One of these days I'll have to do a post addressing all my saws, maybe then I'll figure out how much I've spent on saws, Quite frankly, I don't think I've spent much! Oh, I also wanted to point out the hole at the end of the saw. That wasn't there when I inherited the saw, but I wanted to be able to store this one with the rest of my saws.

So, using my drill press, I put in a hangin' hole. And really, I was surprised at how strong the tool steel was on this saw - it took some good bit of drilling to get through!

Its Natural Habitat

And here she is in her natural habitat! Now you see why I drilled that hole in the end of the blade. You might also notice - this is my biggest saw by a good bit!

Hey - Thanks for stopping by!